Details

:

I. Introduction:

2PCG type permanent magnet high gradient dry iron removal machine, it breaks through the current market application of all kinds of electromagnetic, permanent magnet iron removal equipment mechanism structure mode, innovative research and development of magnetic fluid principle and structure design, the selection of high-performance permanent magnet materials, high background magnetic field and soft magnetic separation medium rod, High magnetic field gradient force is generated to capture the small content of micro - fine weak magnetic iron oxide impurities in the material. The magnetic system is designed with a horizontal semi-closed short magnetic circuit structure, and the working distance of the separation cavity is adjustable. When it is adjusted to 8mm, the background magnetic field is 950-1060MT. The magnetic induction intensity at the sharp Angle of the dynamic magnetic separation medium bar on the two rollers can reach 1.98-2.1T, in order to adapt to the requirements of different mineral material properties. At present, the equipment has been applied to a variety of non-metallic minerals (10-200 mesh) iron removal and purification operations, such as: High purity, refined quartz sand (powder), kyanite and sillimanite, andalusite, dolomite, potassium feldspar, magnesium olivine sand, perlite, bauxite, refractory materials, etc., by the users pay a return visit feedback, fully proved equipment in addition to the effect of iron (excellence), greatly improve the product quality level and reduces the production cost and improve the environmental protection effect.

Ii. Equipment structure:

The machine is equipped with two roller and its internal magnetic system and horizontal installed on the frame, the motor drive mechanism drives the two roller synchronous rotation, on two roller appearance Settings have equidistant, an enfilade cylinder shaped magnetic medium separation, two roller rack protected on both sides of the box, box end device on seismic apparatus and the discharge chute and negative pressure dust collecting interface, The feeding mouth of the receiving groove is connected with the frequency conversion automatic weighing and quantitative feeder. The lower part of the frame is provided with a baffle for the concentrate material channel, a brush roller and an iron connected with miscellaneous.

Three, working principle:

The ore material to be processed is dragged out from the low discharge port of the silo by the automatic weighing quantitative feeder, and fed into the receiving tank of the equipment quantitatively. Under the action of the microvibrator, the material powder is loose, uniform and suspended, and falls to the working cavity of the two rollers (the spacing of the working cavity can be adjusted). The iron oxide impurity in the material is selectively captured and adsorbed on the end face by the sorting bar on the drum. With the rotation of the drum, it leaves the working area with the load, and loses magnetism instantly in the non-magnetic discriminating medium bar. Under the action of the brush roller, it falls into the iron to realize the process of automatic continuous iron removal and iron removal.

Four, specifications and main technical parameters:

|

Model and Specification

|

drum

number

|

Cylinder size

mm’

|

Magnetic field intensity

|

Selected granularity

|

processing

|

motor power

|

Overall dimensions

|

|

2PCG-500

|

2

|

Φ500*1100

|

13000-20000GSadjustable

|

10-200Orders

|

10t/h

|

3kw

|

1500*1350*1800

|

|

2PCG-600

|

2

|

Φ600*1200

|

15/h

|

4kw

|

1500*1450*1800

|

|

2PCG-750

|

2

|

Φ750*1200

|

20t/h

|

5.5kw

|

1700*1700*1800

|

|

2PCG-800

|

2

|

Φ800*1300

|

25t/h

|

5.5kw

|

1700*1700*1800

|

|

2PCG-900

|

2

|

Φ900*1500

|

30t/h

|

7.5kw

|

2000*1700*1800

|

V. Precautions for user selection:

Around because of the produce of non-metallic mineral mineral nature differences exist, the user can according to the concentration of ferric oxide in their mineral content, occurrence state and their distribution in various sizes, than susceptibility, monomer dissociation grinding sieve selected granularity, granularity, in addition to the capacity of the iron requirements and, corresponding equipment specifications and technical parameter table, choose ok.

Note: For the old production line of wet grinding process, no matter how many stages of iron removal processes are in front, only after the ore material is dried or dried, the equipment can be installed in a series before the raw material packaging, and the user who needs ultra-fine products can continue the following process after iron removal by the equipment.

The company's product quality assurance, welcome users to bring material to the site test machine iron removal, to ensure that users to meet the requirements of raw material iron removal.

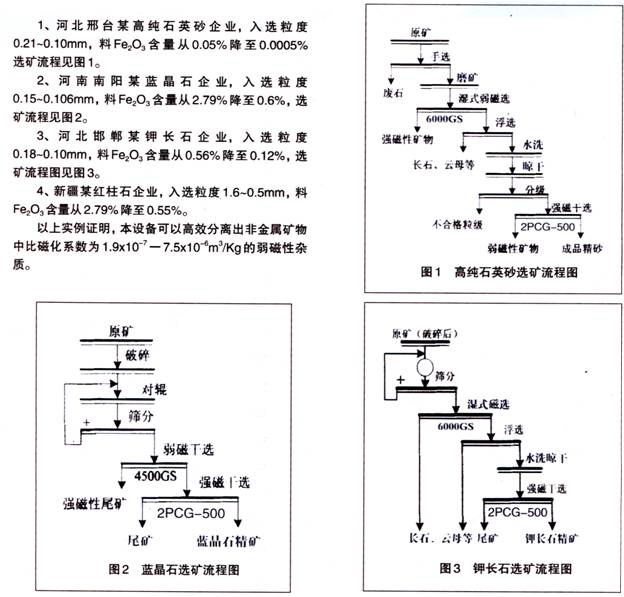

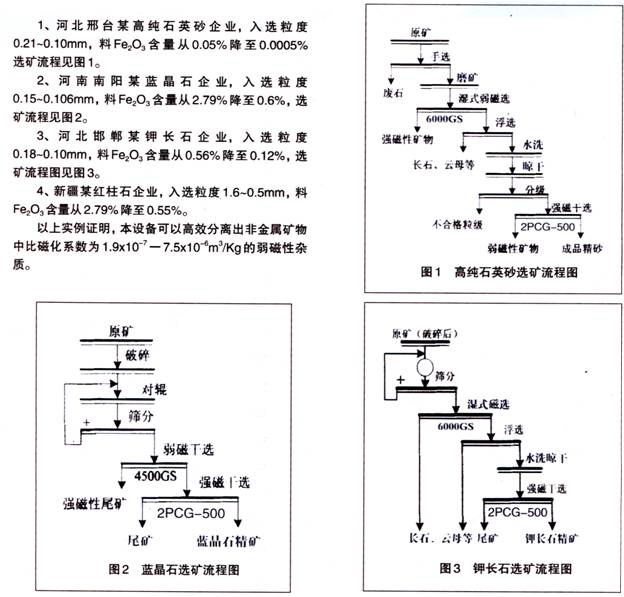

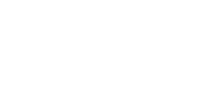

Vi. Application examples and process introduction: